Applications

Steel

Lime is an important ingredient in the production of steel. Quick Lime is used as a flux in steel, metallurgical plants which allows it to lower the concentration of impurities in the steel (above all silica and alumina, but also sulphur, phosphorus…) and so produce slag.

- Lime is used to convert iron into ‘pig iron’. In the blast furnace, finely ground or granular limestone (with a low sulfur and alkali content) is used together with finely ground lime to convert ore into pig iron. The pig iron is later processed into steel.

- Lime is used as a fluxing agent in electric arc furnaces and basic oxygen furnaces. Lime removes impurities (for example, silica, phosphorus, sulfur) from the steel being manufactured. The lime fuses with the impurities to form slag, which separates from the steel and is removed. This process improves the quality of the steel.

- Lime is also used to enhance the refractory life of the furnaces. The magnesium oxide (MgO) in dolomitic lime reduces the tendency of steel slag to dissolve the MgO within the furnace refractory.

Paper Industry

Lime is used in several applications within pulp and paper mills including the pulping process, pH Control and color removal. One of the most common applications is for the sulfite-pulping process. This process uses acid to dissolve the glue (lignin) that holds the fibers (cellulose) together.

- As noted in T 617 – Analysis of lime, “two forms of lime are used in the paper industry: quicklime or unslaked lime and hydrated or slaked lime.” Quicklime (calcium oxide, CaO) is a white crystalline mineral derived from the rapid thermal decomposition of limestone and generally obtained in a kiln; slaked lime (calcium hydroxide Ca(OH)2) is a somewhat-similar-in-appearance white powder that derives from the mixing, or “slaking,” of quicklime with water.

- Each of these forms of lime is incorporated into a different pulping procedure. Ultimately, the primary goal of pulping is to dissolve away the lignin that binds together the cellulose fibers of wood. Each process makes use of lime in different ways to fulfill this task.

Chemicals

limestone, sedimentary rock composed mainly of calcium carbonate (CaCO3), usually in the form of calcite or aragonite. It may contain considerable amounts of magnesium carbonate (dolomite) as well; minor constituents also commonly present include clay, iron carbonate, feldspar, pyrite, and quartz.

Most limestones have a granular texture. Their constituent grains range in size from 0.001 mm (0.00004 inch) to visible particles. In many cases, the grains are microscopic fragments of fossil animal shells.

Water Treatment

Lime in all its forms – quicklime and hydrated lime, as well as calcined dolomite – are the most effective and cost efficient alkaline products used in the making of drinking water, as well as in the treatment of waste water and sludge. In fact, most of the lime that is produced is used to improve the quality of drinking water as well as the water used by industry. Accordingly, lime allows water to be softened, purified, have its cloudiness eliminated, its acidity to be neutralized and its impurities to be eliminated, etc.

Because of all these advantages, explained in more detail below, calcium oxide (CaO) and calcium hydroxide (Ca(OH)2) are used in drinking water purification plants. Calcined dolomite (CaO MgO), can also be used in water treatment plants, for example to eliminate silica from water. This is because the magnesium in the dolomite acts as the main reactive agent for the elimination of silica. The use of quicklime and slaked lime is much less common.

Road Building

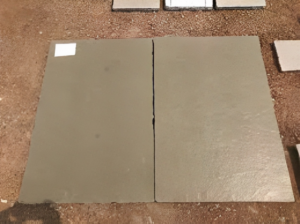

Sand is an essential material for building. Construction-grade sand is the perfect material in road building because of its durability. When you have a strong base layer for your projects, you have solid roads that last a lifetime.

Concrete sand is made from limestone and cement. The mixture of these two materials creates a coarse sand that your road construction team can use as a pavement filler as well as a level medium. The sand size for concrete is typically 20 mm, but it’s 40 mm for mass concrete. If you’re looking for a quality material to make concrete sand with, we provide crushed limestone for your project so you can make the perfect concrete aggregate for road construction.

Benefits of using Pontotoc’s concrete sand include:

- Makes leveling uneven ground or roads easier

- Creates better traction on icy roads

- Easy to pack

- Strong base layer or under paver for roads

Leather

Liming is a process used for parchment or leather processing, in which hides are soaked in an alkali solution. It is performed using a drum and paddle or a pit. Its objectives are:

- Removal of interfibrillary proteins.

- Removal of Keratin proteins.

- Collagen swelling due to the alkaline pH.

- Collagen fibre bundle splitting.

- Removal of natural grease and fats

Liming operations of cattle hides usually last 18 hours and are generally associated with the alkaline phase of beamhouse operations.

Sugar

Lime is used in sugar production, when purifying the juice from beet or cane. Sugar beet is sliced up and passed through a diffuser to extract the sugar juice. Lime, produced from high-calcium limestone, is used in the production process for this essential operation.

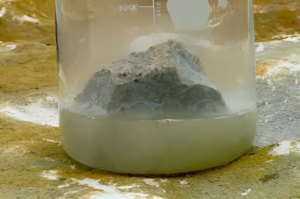

Good-quality milk of lime is required in the sugar process for the sugar juice purification. Lime is used to capture and remove impurities in the juice of sugar beets. 125kg of limestone are used for the production of one tonne of sugar.

Most sugar-processing plants have their own lime kilns, so they need good-quality limestone to burn.

The high-calcium limestone is converted into quicklime in these lime kilns, at a temperature of 900°C. Water is added to this lime to obtain the milk of lime.

Dairy Industry

In two feeding trials lactating dairy cows were fed limestone and in one trial growing dairy heifers were fed magnesium-limestone-buffered rations. Complete mixed rations based on corn silage and corn grain were fed ad libitum. In Trial 1, cows fed a ration with 2.76% limestone consumed 7.36% less dry matter of feed than cows fed a ration containing .11% added limestone, with no effect on milk production.

In Trial II, cows fed a ration with 2.71% limestone had similar feed intakes and milk production but gained more weight than cows fed a ration with .01% limestone. Heifers fed a ration supplemented with magnesium limestone gained .49 kg more weight per day and made more efficient use of feed than heifers fed the nonsupplemented ration. Limestone increased fecal pH from 5.99 to 6.62 in Trial 1, 6.13 to 6.57 in Trial II and decreased loss of starch in feces. Magnesium limestone increased fecal pH from 6.37 to 6.76 and decreased starch in feces from 5.60 to 1.14%. In these trials both limestone and magnesium limestone increased fecal pH, reduced starch losses in the feces, and improved feed efficiency.

Paints

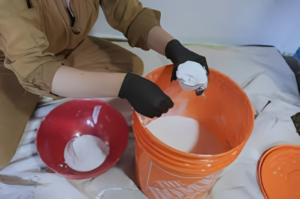

Precipitated Calcium Carbonate ( PCC ) is an innovative product derived from lime stone, which has many industrial applications. PCC is made by hydrating high- calcium quick lime and then reacting the resulting lime slurry with carbon dioxide. The resulting product is extremely white and typical has a uniform narrow particle size distribution. PCC is available in numerous crystal morphologies and sizes, which can be tailored to optimize performance in a specified application.

Precipitated Calcium Carbonate is used as extender and Opacifying Agent in Paint Industry such as Emulsion, Paint & Polishing Agents for Titanium Oxide which imparts Brightness. It has Aragonite and Calcite structure with different particle size distribution and apparent densities

Agriculture Used

Agricultural lime has been used by farmers for years as a soil improver. It’s also a natural, low-cost way to enhance the effects of regular chemical-based fertilizers.

By reducing soil acidity, aglime makes a huge difference to the productivity potential of both arable and grassland farming. Adding limestone helps to stabilize soil acidity while increasing essential mineral content, including calcium and magnesium. This results in improved crop growth and yields.

Benefits of agricultural lime

The application of agricultural lime to farmland leads to five major benefits:

- Increasing pH in acidic soil, reducing acidity, and increasing alkalinity

- A source of calcium for plants

- Improving water penetration in acidic soils

- Improving the absorption of prime nutrients (nitrogen, phosphorus, and potassium) in plants growing in acid soils

- Reducing the need for costly, potentially toxic chemical fertilizers